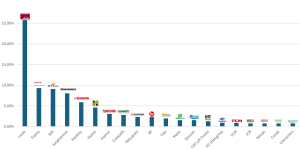

Assistance systems in industrial trucks

An assistance system is a technical, often fully automated solution that supports machine operators in carrying out their logistical tasks. It can provide important information and support, as well as intervene fully automatically where necessary. Increasingly based on artificial intelligence, these systems enhance safety and boost productivity in everyday handling operations.

Digital helpers are everywhere. Drivers know them well: there is a beep when reversing, a beep when moving forwards, and if we ignore it – because the threshold for triggering the warning is set quite low – the on-board computer may even initiate emergency braking. It can be irritating. On the other hand, adaptive cornering lights, adaptive cruise control and many other assistance systems are genuine improvements.

Industrial trucks have long been equipped with a wide range of digital assistance systems. In practice, legal requirements vary depending on the country, the industry and the application. As with any new business investment, it is important to determine what is necessary, useful and productive – and what is not.

For example: The owner of a small company employs three forklift drivers and has three forklifts. When buying a new truck, he chooses a model with PIN-code access because all individual seat and steering-wheel settings are saved and automatically adjusted for each driver. This means he no longer needs to set everything manually. However, he hardly ever drives a forklift himself, and his three drivers do not normally swap machines during day-to-day operations. From an economic perspective it is not essential, but it is a nice extra. Profitability is not always the only thing that matters.

Key assistance systems that prevent accidents and increase productivity

- Adaptive cruise control reduces speed in bends, on uneven ground or when carrying heavy loads.

- Stability and tilt-warning systems detect potentially dangerous tipping angles before the truck becomes unstable and warn the driver in good time.

- Front and rear cameras or mirror-assist systems improve visibility, particularly to the rear and in narrow aisles.

- Lift and load monitoring uses sensors to check load weight, centre of gravity and fork position, issuing a warning if capacity limits are exceeded.

- Load stabilisation and mast-tilt adjustment ensure safe depositing, tilting and lowering of loads, even on uneven ground, and reduce mast sway at height.

- Automatic fork positioning with laser sensors enables precise pallet handling while preventing damage to goods.

- Pre-settable driving modes, similar to those in cars, provide added safety for beginners or full performance for experienced operators, depending on the task.

- Sensorimotor controls adapt to the driver’s handling style; the system responds sensitively to steering movements and lever pressure, making operation more intuitive (steering, acceleration).

- Automatic ramp-hold function prevents the truck from rolling backwards on slopes as soon as the accelerator pedal is released – the driver can simply step off; when they return and accelerate, the brake is released automatically.

- PIN-code and other key systems prevent unauthorised use and automatically apply the stored preferences of each driver.

- Adaptive load-distribution and gripping-angle systems adjust gripping and lifting angles to the size and shape of the load.

- GPS and navigation systems optimise routes in outdoor areas and large indoor facilities and reduce travel times.

Systems with limited benefit (gimmicks)

- Excessive numbers of cameras or sensors without meaningful application distract more than they contribute to safety.

- LED “light shows” – too many warning lights (rear or side) – reduce the actual safety benefit because they distract more than they alert.

- Complex network integrations without clearly defined operational processes create more cost than benefit and increase maintenance requirements.

Practical tips for new purchases

- Create a checklist with your drivers of 5–10 aspects of the current forklift that could be improved. Then check how often these issues occur. Ask your forklift or warehouse-technology supplier for a quotation including the relevant assistance systems. Compare the costs and benefits – and remember that ergonomic workstations often result in fewer sick days and increased motivation, leading to higher performance.

- Safety first: choose systems that demonstrably reduce risks (anti-tipping, collision-avoidance, load-warning systems).

- Check compatibility: systems should match your load types, pallets, warehouse layout and existing fleet.

- Training: assistance systems are only effective when drivers recognise and accept them as useful. This also requires regular updates and appropriate training.

Conclusion

Assistance systems improve safety, reduce damage and increase productivity. In principle, all forklift trucks should be equipped with load monitoring, visual detection and obstacle-detection systems. Extravagant hardware or software without clear benefit should be avoided.

Despite these technological aids, the operator remains responsible: assistance systems do not replace daily visual inspections and do not absolve anyone – neither warehouse managers nor drivers – from their responsibility for the safety of people and goods in everyday operations.

Looking for devices?

Don’t want to miss anything?